Home > Products

The future is here with Copper-based inks, pastes, polymers and nanoparticles. Our patented formula keeps Copper (CU) from oxidizing to allow this metal to maintain high conductivity and low resistivity. Our copper based conductive products perform like silver but at half the price.

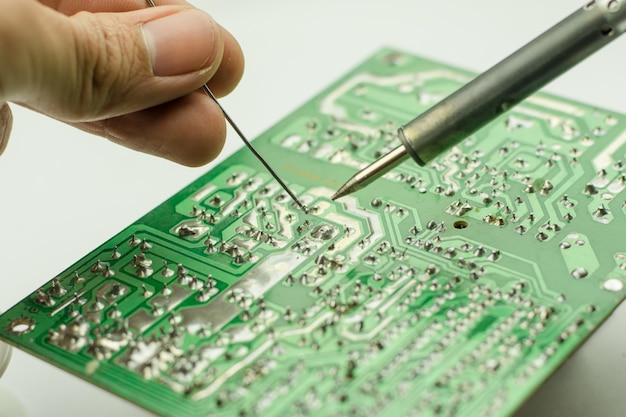

PolyC Plastics and Composites offers copper nano particles, inks, pastes, and polymers as base products for a wide array of applications. We can assist with R&D for specific applications, manufacturing needs and make products to specs. Our conducive products are suited for thermopolymers, high performance electronics, wearables, antenna, printed circuit boards, solar panels and much more!

Our antioxidant coating does not only keep steel from rusting, but it also reverses rust damage. This revolutionary technology is hydrophobic, self-healing and suitable to be incorporated into paints, films, and epoxy type coatings. Self-healing properties of the polymer ensure scratch resistance and provides the ultimate corrosion control for material integrity.

Industries suited for our coatings include infrastructure, aerospace, automotive, marine vessels, manufacturers, and more. This is the perfect material to coat rebar, steal, bridges, vehicles, and vessels. Our team can make coatings to desired specifics such as transparent or opaque, flexible or rigid, and can explore other physical properties like static dissipating, dielectric and conductive.

Cytoxicity studies on our polymer demonstrated a safety profile on par with, if not better then industry standard medical grade polymers used for implantations. The ability to conduct electricity coupled with the compatibility with life, we see a growing number uses for FDA approved applications in the medical device field, wearables electronics, and implantables into the future.

This would be a perfect tech to couple with the telemedicine revolution – sensors for various testing/monitoring system. Our first medical sensors tested were ECG electrodes which outperformed industry standard when exposed to aqueous environments. PolyC Plastics and Composites can modify the polymer blend, manufacturing techniques, and other specific requirements to meet your project needs.

Clink the link below to receive a quote, receive more information or share your vision on how we can help you.

© Copyright 2024 by Polyc. All rights reserved.